Bricks

WATERSTRUCK BRICKS

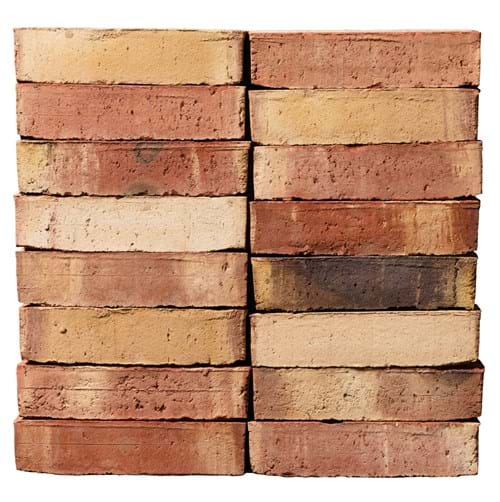

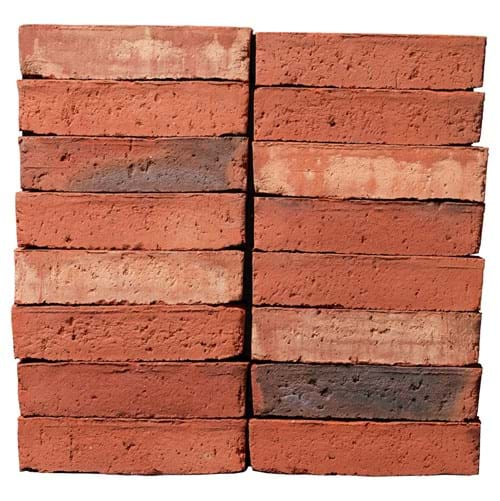

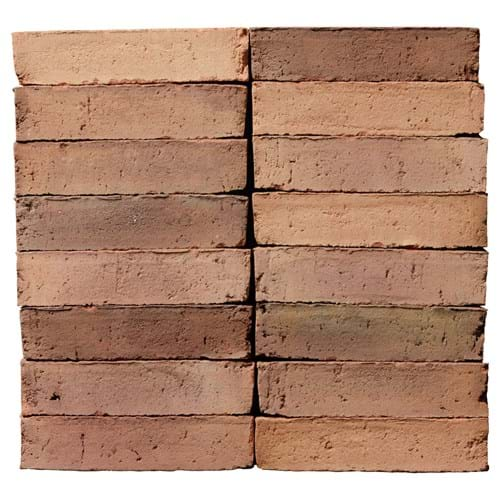

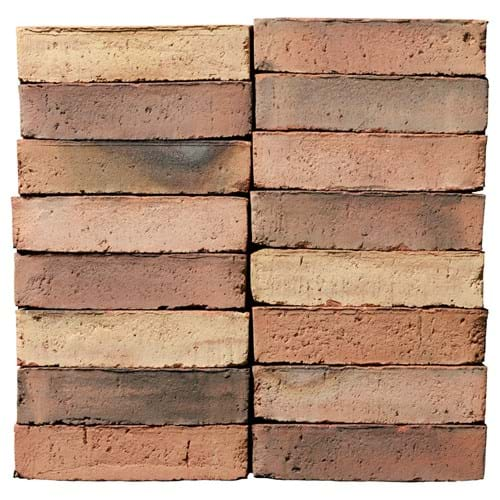

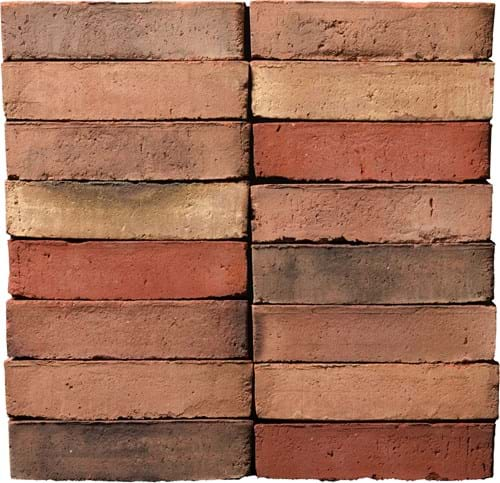

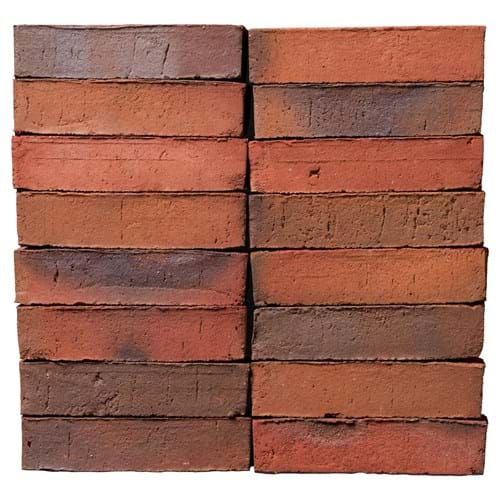

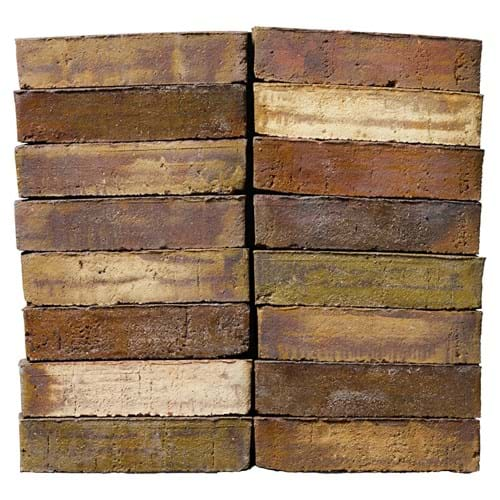

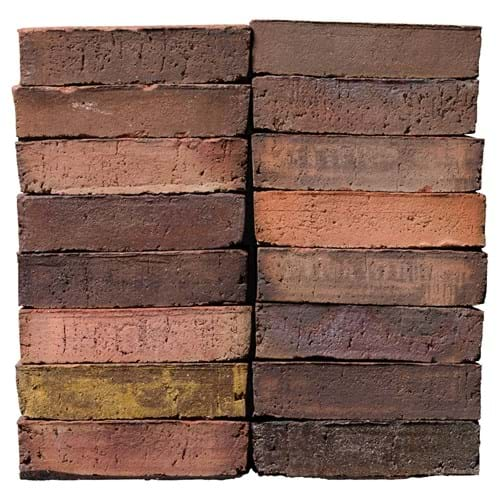

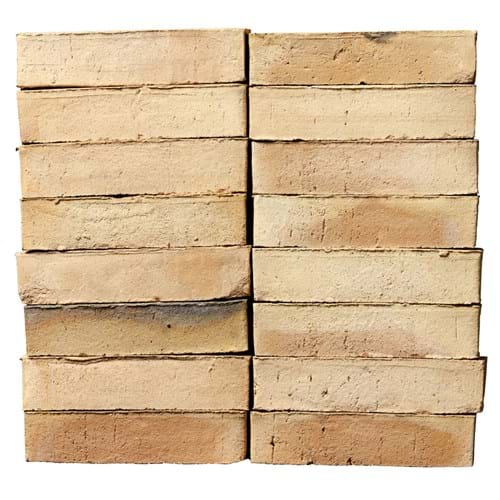

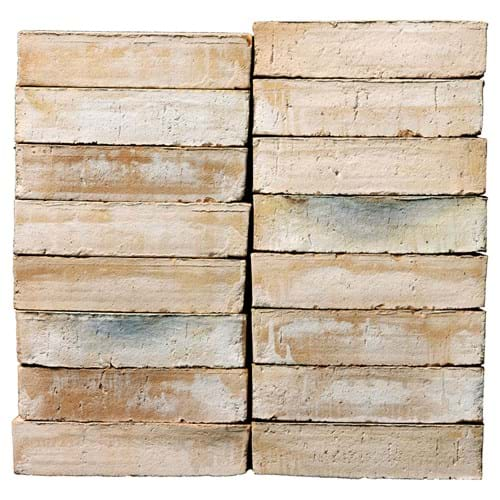

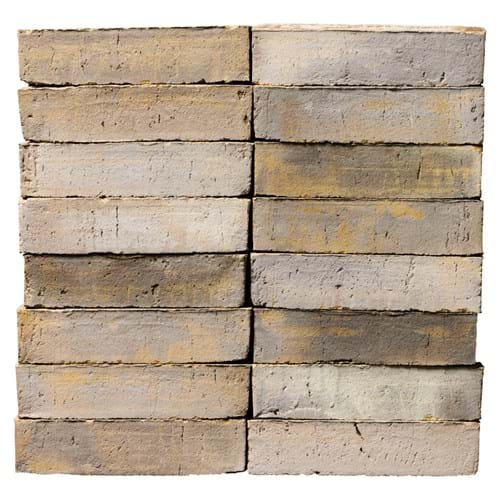

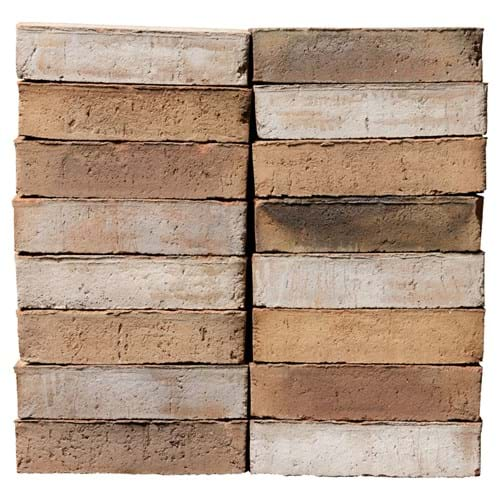

Petersen Tegl's waterstruck bricks are made on machines that reproduce the way in which bricks are made by hand. This engenders the uniformly, non-uniform look of the brick with four equal fronts and a uniquely vibrant colour play.

Our range of classic bricks are produced in the formats DNF, FF and HF and in 39 variations in a wealth of colours and three formats.

Furthermore we can manufacture bricks in customised colours and geometries according to the customer’s specific requests.

Product leaflet DOWNLOAD >

When produced, the bricks are shaped into moulds. Excess clay is removed, and using the water as release agent, the mould can be lifted off. Due to this production method minor dimension variations and cracks appear, but these have no impact on the strength and durability of the bricks.

BRICKS AND FROST

Petersen Tegl's bricks are frost resistant. We primarily use clay from the brickworks' local surroundings where clay has been dug for brick production for several hundred years.

At the brickworks, the clay is pugged, moulded and pressed using techniques similar to the processing method used when all work was done by hand. The method gives the best possible texture with capillaries and air voids that allow the water to expand when it freezes without damaging the brick. The fact that bricks can absorb water does therefore not involve a risk of frost damage.

See the frost and brick information sheet DOWNLOAD >

The colours are indicative only.